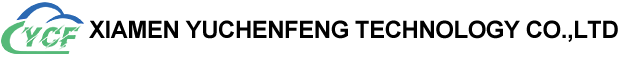

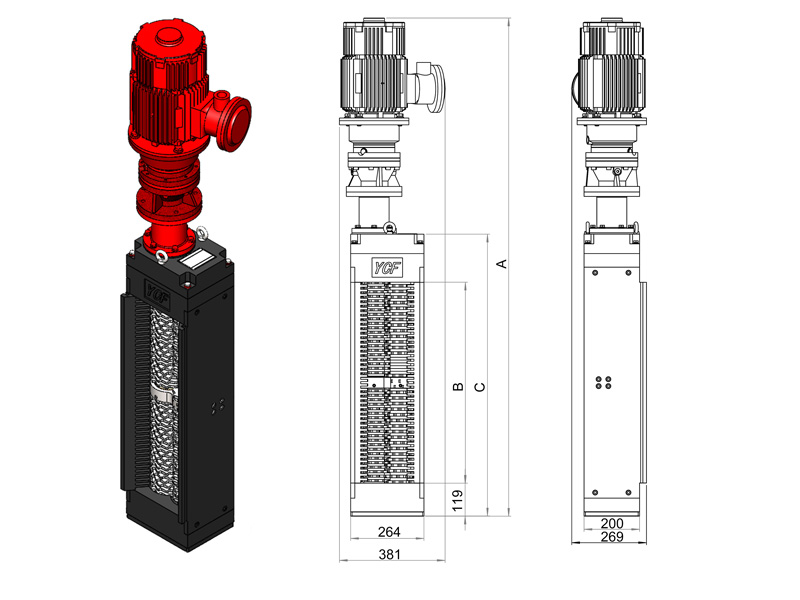

YCFC-N340

Operation Principle

1.Solids enter grinders through open channel.

2.Solids pass through cutters for size reduction.

3.Solids are cut into smaller particles and no threat to downstream equipment.

Materials of Construction

Motor: Customized, multiple power options

Reducer: Planet gear reducer, good ability to against the load impact

Cutter and spacer: heat-treated alloy steel 4130 with surface harden evenly.

The hardness is not less than 45~50HRC

Shaft: heat-treated alloy steel 4140

Mechanicals Seals: Tungsten Carbide faces

Housings: Ductile cast iron ASTMA 536

Frame: Stainless steel(304,316)

Mechanical Characteristic

Ease and Flexibility of Installation

● Adapts to most existing channels and pumping stations with little or no modification

Mechanical Seals

● Pressure capability up to 6.3kg/cm2;

● No seal flush required and no packing gland to adjust;

High-Flow Side Rails

● Increases flow capacity and decreases head loss

● Directs solids into the cutting chamber

Dual Shaft Design

●Low-speed, high torque grinders handle rags, rocks, wood, clothing, plastics and other debris

●Capable of handling a wider variety of solids than single shafted machine

Cutter Options

●Customized cutters with various tooth configurations to meet special application

Low Profile Bottom end housing

● More of the cutting chamber is utilized during low flow

Top Fastening Devices

● Easy to fasten without lifting out of the channel

Control System Function

● PLC Control Cabinet with liquid crystal display, real time monitoring loading

● MODBUS standard field bus Communication interface and remote controllable

● Time adjustment, runtime and failure records query

● Automatic Reversal Function, time and times setting of reversal

● Leakage, Over Capacity, Overheating, Short Out and Lack of phase protection functions

● Authority setting function